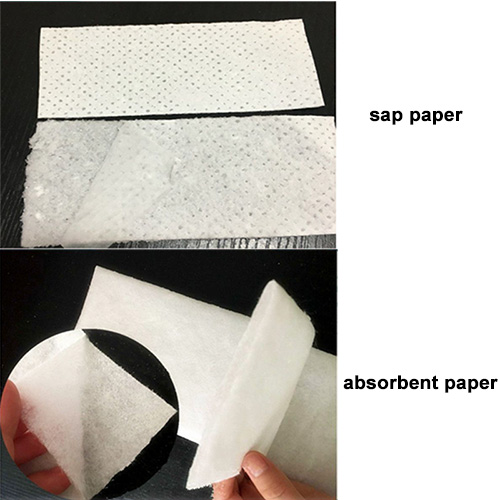

SAP paper and absorbent paper are two materials that are widely used for their absorbent properties. SAP paper is mainly composed of a combination of materials including tissue paper, super absorbent polymer (SAP) and fluff pulp. Whereas absorbent paper is composed of airlaid paper, SAP and fluff pulp. This article will explore the differences between these two types of paper.

Composition:

SAP paper: SAP paper consists of three parts, including thin tissue paper, SAP and loose cellulose pulp. The thin tissue layer plays a supporting role in the whole structure, and SAP (super absorbent polymer) is the key to achieve high water absorbency. Loose cellulose pulp is used to provide softness and other physical properties.

Absorbent paper: Absorbent paper is made up of three parts, including airlaid paper, SAP and fluff pulp. The airlaid paper layer has a high porosity and air permeability, which helps to improve water absorption, while SAP is responsible for absorbing large amounts of liquid. Fluff pulp is used to enhance structure and provide comfort.

Water absorption performance:

SAP paper has excellent water absorption performance by using super absorbent polymer (SAP). SAP absorbs large amounts of liquid quickly and locks it into the paper structure, keeping it dry. In contrast, absorbent paper has lower water absorption performance, but its loose structure provides a larger water absorption surface area, which is suitable for occasions that need to absorb water for a longer time.

Thickness:

SAP paper is known for its thin and lightweight characteristics. Due to its relatively thinness, SAP paper is often used in thin products such as ultra-thin diapers and thin sanitary napkins. Absorbent paper is relatively thick and is more suitable for products that require larger absorption capacity and extra protection, such as night diapers and extra-large sanitary napkins.

Application areas:

SAP paper is widely used in the production of diapers and sanitary napkins. Its water absorption properties make it an ideal choice for high absorbency and thin appearance requirements. Absorbent paper is also used in some special occasions, usually for products that need to absorb water for a longer time.

Conclusion:

Although SAP paper and absorbent paper are similar in composition, there are significant differences in thickness and use. SAP paper is thinner and suitable for products that require high absorbency and thin appearance, such as ultra-thin diapers and thin sanitary napkins. Absorbent paper, on the other hand, is thicker and is suitable for products that require greater absorption capacity and added protection, such as nighttime diapers and oversized sanitary napkins. For manufacturers, choosing the right material is determined by the specific needs and market positioning of the product.